Introduction to Production Part Approval Process (PPAP) Presentation

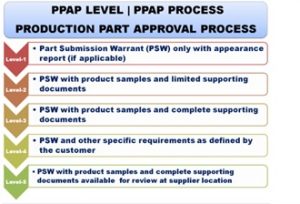

Production Part Approval Process (PPAP) is the industry standard that aims at ensuring engineering design and product specification requirements are achieved. Using the PPAP guideline, suppliers and customers understand the requirements needed to obtain part approval of supplier manufactured deliverables. It is applicable to all parts and deliverables, and through application of PPAP principles reduces delays and non-conformances during part approval process.

If you need to become versed on the procedures, reporting requirements and activities specified by the PPAP manual then this course is for you!

The aims of this course are to:

- Explain the role of Production Part Approval within the product realisation process

- Illustrate how various organisational functions contribute to PPAP

- Impart an awareness of the core tools and techniques involved in PPAP

- Describe the items required for PPAP approval

- Describe the requirements for product and process validation prior to the start of serial production

- Illustrate the relationship of PPAP with Advanced Product Quality Planning (APQP).

- Become a Quality Management & Training PPAP Certificated Engineer

What are the benefits being a Quality Management & Training PPAP Certificated Engineer?

- Demonstrates ability to complete a part approval process

- Confirms ability to ensure parts conform to customer requirements

- Proves knowledge of the evidence required to show process stability

- Confirms knowledge of the controls product and process change process

- Demonstrates ability to follow OEM Customer Specific Requirements and Customer Specific Requirements (CSRs).